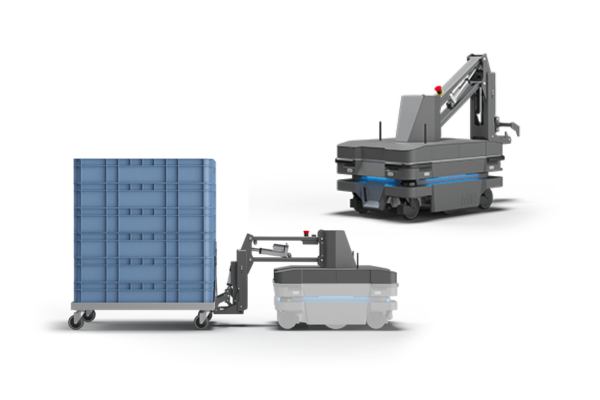

Autonomous mobile robots (AMR)

AMR integration to increase the flexibility of our robots.

The integration of autonomous mobile robots (AMR) with an industrial robot offers a practical solution for performing pallet changeovers without requiring the intervention of a human operator in the workspace.

This synergy increases the flexibility of our palletizing robots, enabling them to perform pallet transitions automatically in response to SKU or other parameter changes. In addition, this approach offers the advantage of maintaining continuous operation of the industrial robot during pallet changeovers, as no human intervention is required for this task, thus eliminating the need for additional safety devices.

Increased efficiency

AMRs take care of repetitive tasks, freeing up staff for complex, value-added tasks.

ROI in less than 2 years!

AMR's ease of integration means minimal downtime, and the ability to define other roles for the technology as it becomes integrated into operations.

Flexibility

In the face of rising demand, traditional technologies such as forklifts and AGVs are not enough, due to the considerable time and cost required to change production patterns. Agile AMRs, equipped with sensors to bypass obstacles, offer a solution.

Autonomous mobile robots (AMR), self-navigating

Mobile robots, like Omron and MiR, offer exceptional versatility. Manufacturing, warehouses, clean technologies and laboratories are just a few examples of environments where the mobile robot is ideal. It improves the flow of transport in factories.

Autonomous Mobile Robots (AMR) by MiR

These robots are not confined to logistics companies; they are also popular in the manufacturing industry, particularly in the plastics sector. For example, they can collect parts from various injection molding machines and transport them to the warehouse.

Autonomous Forklift

The VisionNav product stands out for its integrated forklift functionality, eliminating the need to use stands to pick up a pallet from the ground. Basically, the robot autonomously navigates its environment and instantly responds to transport requests in real time.

Previously, factories often used train-like systems with a magnetic strip on the floor, limiting the robots' flexibility to change circuit or adjust their navigation. What's more, in the event of congestion along the way, several robots could get stuck, leading to interruptions in the customer's production flow.

The robots are equipped with fleet management software that ensures automatic dispatching. This software analyzes the robots available, and identifies the closest and most suitable one to carry out the requested mission, taking into account the priority assigned to each mission.

Frequently asked questions

Compared with MiR and Omron, VisionNav can pick up pallets directly from the ground and stock them at height.

Autonomous robots are equipped with mission management and fleet management software to automatically manage missions and movements. These systems analyze available robots, determine which is closest to the mission in hand, and take mission priority into consideration. In this way, robots can be directed efficiently and optimally within the plant environment, avoiding unnecessary stoppages and maximizing productivity.