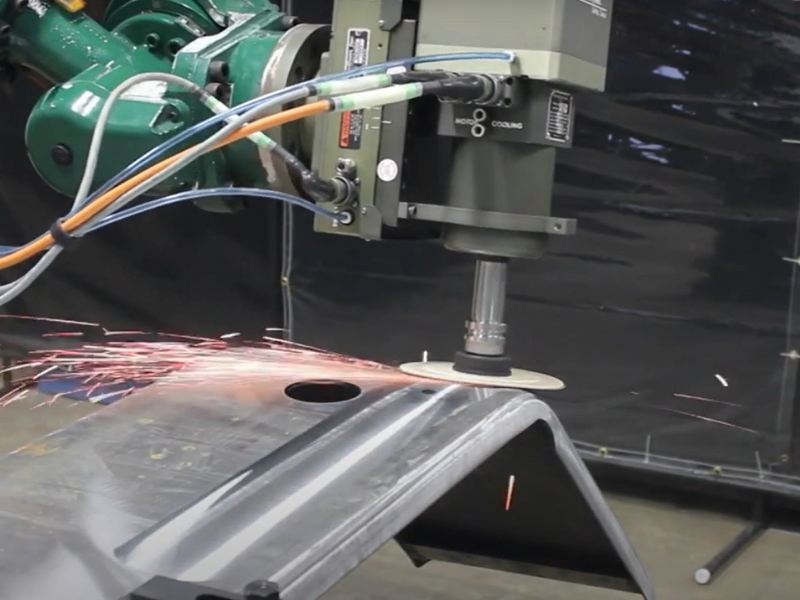

Sanding, Deburring & Surface Finishing

Our Services and Applications

- Sandblasting

- Deburring

- Polishing

- Marking

- Cutting of injection points

- Pre-assembly / assembly

- Tool changes / compensation

Key advantages

Fast return on investment :

Our solution automates your processes, increases productivity, reduces rework and solves labor challenges. Return on investment is often achieved in a matter of months, accelerating your transition to automation.

Consistent quality of sanding:

Employee skill levels vary, resulting in uneven quality of finished parts, which may be over-processed or manually subcontracted.

Reducing waste:

Non-automated processes require excessive amounts of abrasive, as incorrect application of force can lead to problems such as abrasive flaking due to excessive pressure, or lack of fracturing due to insufficient pressure. In comparison, automation ensures higher part quality and extends abrasive life by 200-300%.

Frequently asked questions

Our robotic sanding and finishing services are compatible with a wide range of materials, including metal, plastic, wood and glass.

By automating the process, we also reduce abrasive losses by avoiding errors such as over- or under-application of force.

By minimizing human error, optimizing the use of materials and reducing labor costs, our customers often experience a rapid return on investment, usually achieved in just a few months.