The pre-engineering phase is a crucial stage in the development of a robotics project. It involves clearly defining the customer's needs, identifying potential solutions and assessing the project's feasibility. This phase is essential to ensure the success of the final project, and to avoid unpleasant surprises along the way. A synonym for this stage is the definition of specifications.

What we often see is the first step being the definition of the specifications, followed by a pre-engineering stage focusing mainly on the elimination or mitigation of risks. In short, these are two terms commonly used to describe the pre-project stage in robotics and automation.

Key stages in pre-engineering

- Defining objectives and requirements: The first step is to clearly define the project objectives and the specific requirements related to the manual process we are seeking to automate. This involves understanding the existing processes, the challenges encountered and the desired results. It's very important here to collect and analyze data, and to avoid relying on our intuition, on what we think we see. The data will speak for itself.

- Site and ergonomics analysis: A thorough site and ergonomics analysis is essential to identify physical constraints, safety considerations and the fluidity of the production process. This enables us to select the right robot, equipment and solution to ensure seamless integration into the working environment.

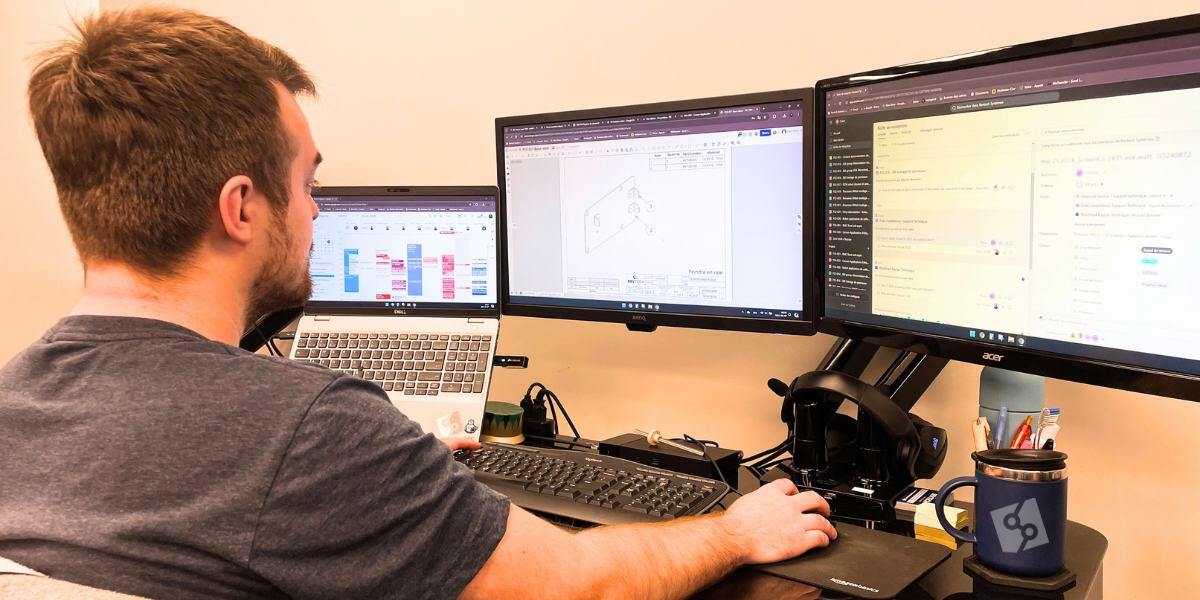

- Preliminary design and simulation: Based on the information gathered in the previous steps, a preliminary design of the robotic system is drawn up. Simulations can be used to evaluate system performance and identify potential problems before implementation.

- Cost and time estimation: Once the preliminary design is advanced, an accurate estimate of the project's cost and schedule can be established. This enables the customer to make informed decisions about the project.

- Objectives to be reached: At this stage, it is essential to identify the objectives to be reached by the automated/robotized system. Cycle time, quality, precision, reliability and more. It's important to put concrete, realistic figures on the table. Be careful not to aim for excessive quality or cycle times that are inconsistent with the rest of the line. Normally, collecting your current production data will provide a good basis for the goals to be achieved with the automated system.

- Validation of the project: A prototype or demonstration can be created to validate the project and obtain customer approval before moving on to the detailed engineering phase.

Transition to the next phase

If the results of the pre-engineering phase are positive, the project can move on to the next phase, which is generally the detailed design and engineering phase. The design phase consists of designing the robotic system in detail and drawing up the technical plans.

Identification of SRED potential

The pre-engineering phase is also a good opportunity to identify the research, development, science and technology (RDST) potential of the project. This involves identifying the areas in which research and development might be needed to find or improve the proposed solution. SRED potential can be quantified by assessing the costs of research and development, as well as the potential benefits of research and development.

The basis of a successful robotics project

The pre-engineering phase is an essential stage in the development of a robotics project. It enables you to clearly define the manufacturer's needs, identify potential solutions and assess the project's feasibility. Spending time in the pre-engineering phase can increase your chances of project success.

At Revtech Systems, we're here to support you every step of the way, offering you our expertise and know-how. Contact our experts to discuss your project and find out how we can help make it a reality.