Robotic and Automation Pre-Engineering

Prepare Your Automation Project

Before jumping into action, careful planning is essential. At Revtech Systèmes, our pre-engineering service supports you through the critical first steps of any robotics, automation, or machine vision integration project.

The goal: define your real needs, validate feasibility, and lay the groundwork for a solution that is efficient, practical, and cost-effective.

Why Invest in Pre-Engineering?

Automating a process without a clear overall vision comes with major risks: cost overruns, delays, and missed performance targets. Pre-engineering helps you:

- Clarify your needs and objectives

- Validate technical and economic feasibility

- Compare multiple technology options

- Structure the project with clear, costed phases

- Build a professional and detailed specifications document

Our Pre-Engineering Approach – Step by Step

- Needs Analysis

Identify key challenges, constraints, product types, volumes, and desired levels of automation. - On-Site Diagnostic

Site visit, measurements, observation of flows and interactions, and documentation of existing processes. - Ideation & Technology Exploration

Development of several robotic solution concepts, performance expectations, and possible configurations. - Technical Pre-Validation

3D modeling, feasibility testing or simulations, and preliminary selection of technologies (robots, vision systems, conveyors, etc.). - Economic Evaluation

Estimated costs, return on investment analysis, and comparison of solution options. - Project Planning

Phase breakdown, preliminary timeline, estimated budget, and strategic recommendations. - Delivery of the Pre-Engineering Report

A clear, structured document—ready to support calls for tenders, funding applications, or project execution.

Client Case: Food Processing Company

A food processing company is looking to automate a strategic step of its production process to meet three key objectives:

- Reduce product rejection rates caused by poor positioning

- Improve precision, which is currently managed by mechanical guidance and manual intervention often leading to non-conformities

- Lower production costs by reducing reliance on manual labor for this operation

Revtech Systems Involvement

Revtech supported the project through a structured pre-engineering and techno-economic analysis approach:

- Process assessment: Full review of the current workflow, observation of manual handling steps, and identification of the root causes of non-conformities

- Measurement and constraint analysis: Validation of product dimensions, tolerances, throughput rates, and physical characteristics

- Cycle time evaluation: Comparison of current cycle times vs. what's needed to support projected growth

- Pre-engineering brief: A detailed document outlining functional requirements, technical inputs, critical constraints, performance targets, and budget ranges

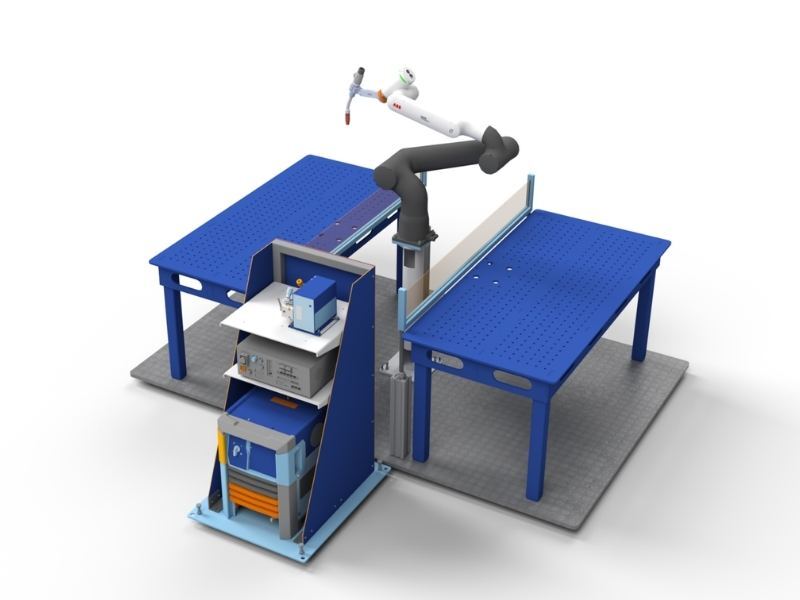

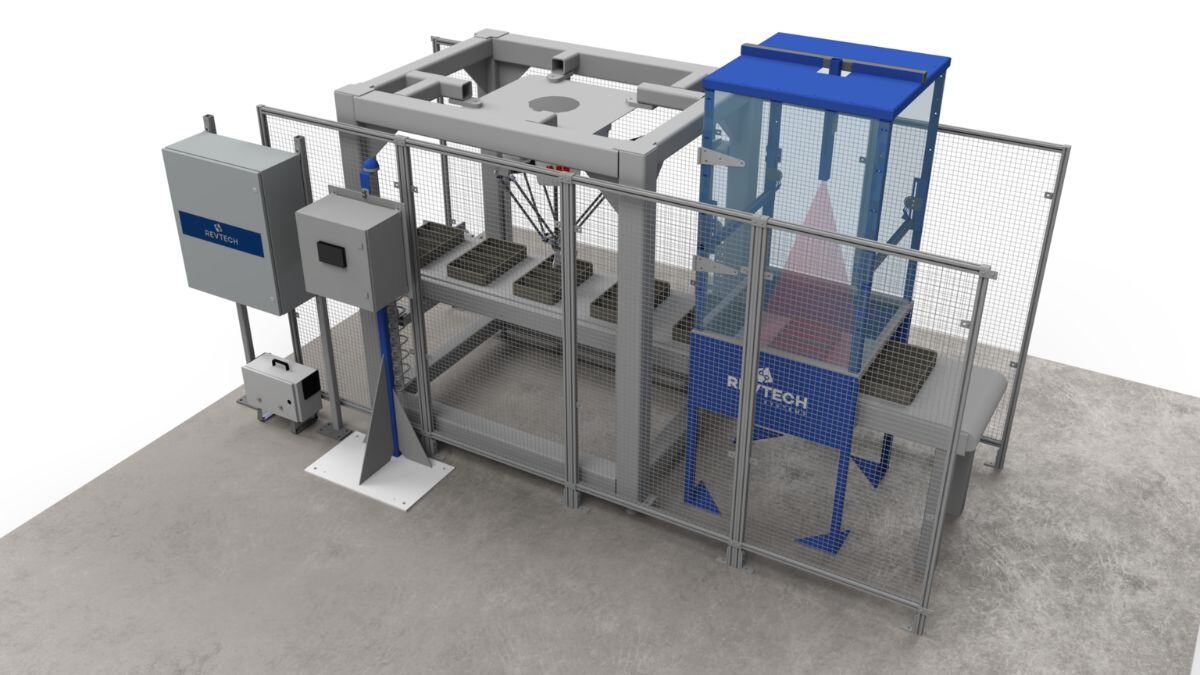

- Preliminary concept development: Robot cell design combining robotics, gripping, machine vision, and interface integration with existing equipment

- Cycle time simulation: Virtual validation to confirm that the proposed concepts can meet throughput and precision targets

- Budget and timeline proposal: Progressive and realistic project plan based on validated concepts

- Full techno-economic evaluation: ROI analysis factoring in labor cost savings, waste reduction, and increased production capacity

Project Results

Thanks to Revtech’s structured technical and economic analysis, the company was able to quickly validate the project and make an informed decision. A solid technical specification document now ensures alignment with vendors, paving the way for implementation.

Project Highlights

- Expected rejection rate reduction: > 50%

- Target product positioning accuracy: ±1 mm

- Estimated labor reduction: 1 to 2 operators per shift

- Estimated ROI: < 18 months

Conclusion

This project illustrates how a well-structured pre-engineering and simulation process can do more than just build a solid solution it also helps secure leadership buy-in with clear, tangible data. Revtech acts as a catalyst between your performance goals and the right technology solutions, tailored to your specific context.

Frequently Asked Questions

The cost varies depending on the project’s complexity, but a typical mandate ranges between $7,000 and $25,000.

Typically between 2 to 6 weeks, depending on data availability and the number of required site visits.

Yes. We are system integrators and can handle engineering, manufacturing, programming, installation, and support. It’s a turnkey service.

.png?width=250&height=125&name=Untitled%20design%20(77).png)

.png?width=250&height=125&name=Untitled%20design%20(85).png)