- Object Detection: Robots are learning to "see" and grasp objects without rigid configurations—a flexibility that saves time and effort.

- Workspace Monitoring: Imagine a robot checking if tools are intact. AI ensures operations run smoothly by identifying what is correct or incorrect before the next step.

- Effortless Realignment: Need to change a robot’s tasks? AI handles alignment seamlessly, reducing downtime for setup.

- Smarter Path Planning: Say goodbye to tedious waypoint programming. With AI, robots navigate complex workspaces with precision.

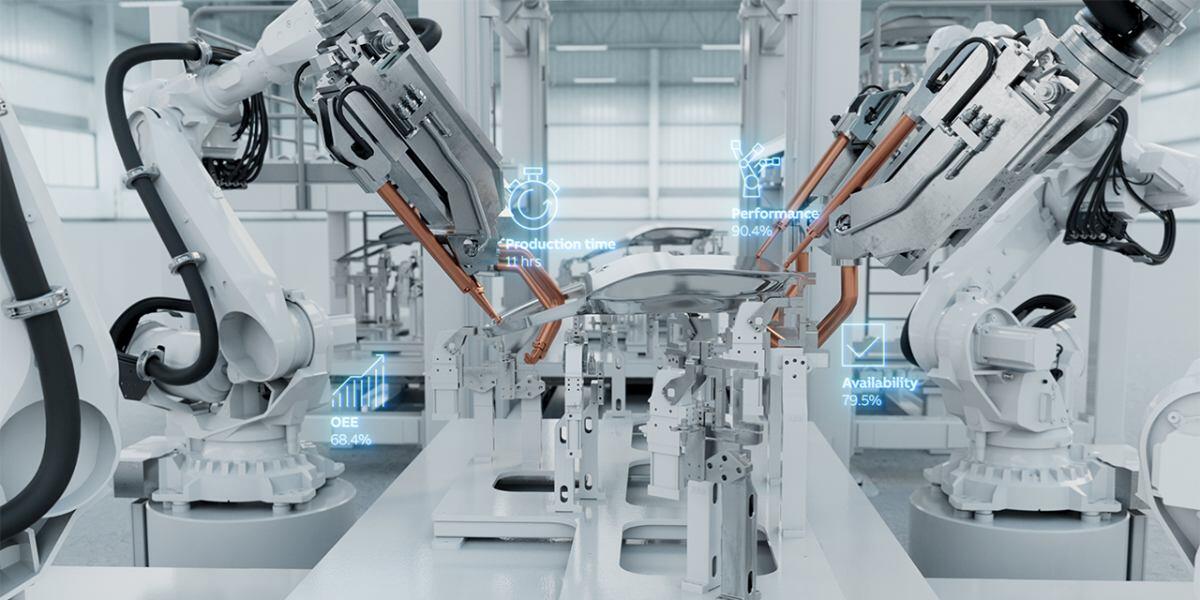

Imagine your robots seeing, thinking, and adapting like never before. AI is no longer just a buzzword. This technology is quietly transforming manufacturing, solving problems, and unlocking efficiency where it matters most.

The Future of Robot Programming

Artificial intelligence is set to revolutionize how we program robots, shifting from line-by-line coding of movements and I/O to high-level behavior commands for task completion. Techniques like imitation learning, reinforcement learning, vision-language-action models, and foundational robotics models offer promising paths for adaptive robot control. These advancements will simplify our interactions with robots and enable solutions for complex tasks.

Integrating AI into Existing Applications

For a manufacturer (SME) newly adopting cobots, understanding how these technologies provide short-term benefits can be challenging. However, solutions exist to handle workspace variability while delivering the speed and precision businesses expect. This approach reassures manufacturers, proving that technological maturity is within reach.

AI-Powered Vision Systems with Deep Learning

Industrial vision is already widely used in manufacturing for locating and inspecting parts. Yet fewer than 20% of cobot applications leverage vision systems. Why? Most users invest time and money in creating fixtures for parts, sacrificing the added flexibility vision offers.

With deep learning-based vision systems, a model can now handle environmental variations using just a few hundred images—compared to the tens of thousands previously needed. Pretrained models available on the market can be quickly repurposed for various industrial applications, reducing integration costs and effort.

FAQ on Robotics and Artificial Intelligence

- How does AI enhance robotics in manufacturing?

AI enhances robotics by providing adaptability, vision, and decision-making capabilities. It enables robots to detect objects, plan complex trajectories, and respond to environmental changes in real time, increasing efficiency and versatility. - What are the benefits of AI-based vision systems?

AI-based vision systems are more flexible than traditional systems. They can identify objects under varying lighting conditions or on different surfaces, requiring fewer data for training. This makes them ideal for natural products with infinite variations, reducing implementation costs and time. - What is reinforcement learning in robotics?

Reinforcement learning allows robots to learn through trial and error to complete complex tasks. By rewarding correct behaviors, robots gradually improve their performance. - Why integrate AI into existing processes?

Integrating AI reduces downtime, enhances precision, and manages variability in work environments. It also boosts productivity and competitiveness for businesses.