China, often described as “the world’s factory,” is no longer focused solely on producing at scale, it is fundamentally transforming how it manufactures. Today, Chinese factories are investing massively in robotics and intelligent automation to address growing challenges such as rising wages, labor shortages, and intense global competition. This shift is highly relevant and deserves careful consideration from a Quebec perspective.

Rapid Growth in Robot Adoption Among Manufacturers

Over the past decade, the number of industrial robots deployed on production lines in China has increased more than sixfold, surpassing 1.7 million installed units. This makes China the third-highest country in the world in terms of manufacturing robot density, just behind South Korea and Singapore, according to data from the International Federation of Robotics.

More recently, China crossed the milestone of 2 million industrial robots in operation, accounting for 54% of global demand in 2024. This firmly positions the country as the world’s largest industrial robotics market by a wide margin.

This acceleration is driven by targeted investments in advanced automation and artificial intelligence technologies, along with ambitious industrial strategies aimed at modernizing the entire manufacturing ecosystem.

Smart Factories Focused on Efficiency and Cost Control

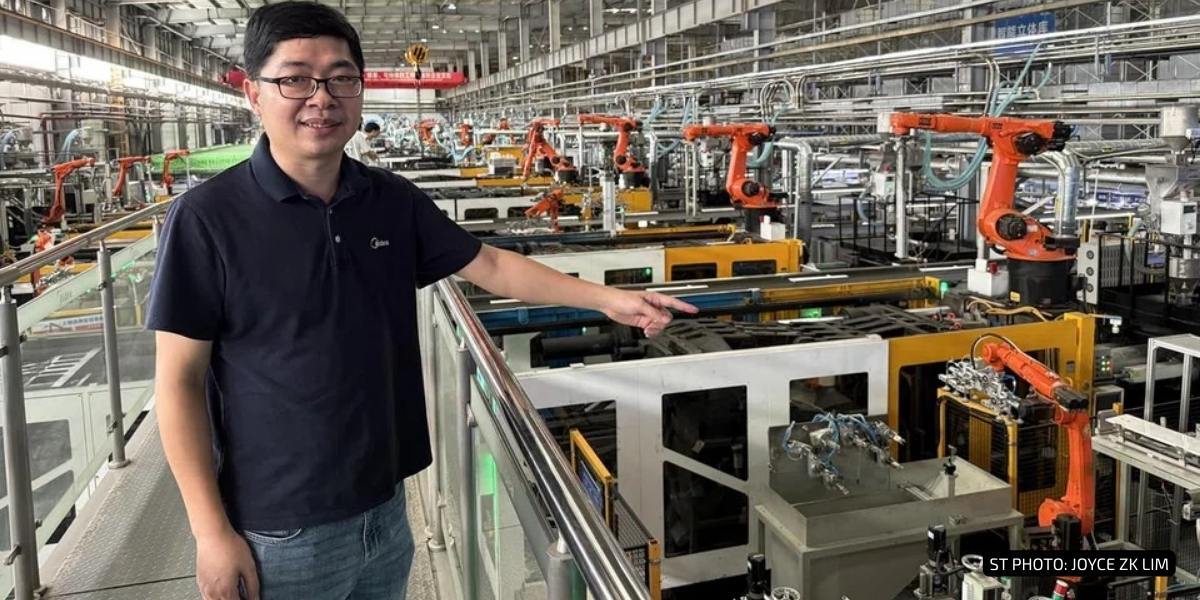

In many Chinese factories, robotic production lines operate 24/7, without interruptions or human fatigue, a model sometimes referred to as “dark factories.” This level of automation helps maintain low unit costs despite labor pressures and tariff challenges, while significantly increasing output.

In some cases, combining industrial robots with AI and advanced analytics improves operational precision, resource utilization, and production speed, levers that remain underutilized in many Quebec manufacturing operations.

Economic and Structural Impacts

Large-scale robotization in China is not only a response to labor shortages; it is part of a broader national strategy to move up the industrial value chain. The Made in China 2025 plan set clear objectives to transition the country toward higher value-added sectors, where robotics and automation play a central role.

Economic data also shows that, in China, the adoption of industrial robots is associated with measurable productivity gains at the company level, with benefits materializing relatively quickly after implementation.

And in Quebec? A Call for Reflection

Like China, Quebec is facing a shortage of skilled workers across many manufacturing and operational sectors. Robotic automation can help reduce reliance on repetitive manual tasks while freeing talent to focus on higher value-added activities.

In a globalized market where supply chains are being reshaped, a proactive approach to robotic adoption can significantly boost productivity and reduce unit costs, key factors in retaining and attracting manufacturing activities locally.

As China’s experience demonstrates, integrating robotics is not merely about adopting new tools; it requires a comprehensive transformation of processes. This means rethinking how operations are designed, measured, and continuously improved.

Source and photos : www.straitstimes.com