Mechatronics and robotics are two technological fields that are often confused because they share several common elements, including automation and the use of mechanical and electronic systems. However, these two disciplines have distinct objectives and applications. Understanding the difference between mechatronics and robotics is crucial for any company looking to integrate automation into its processes.

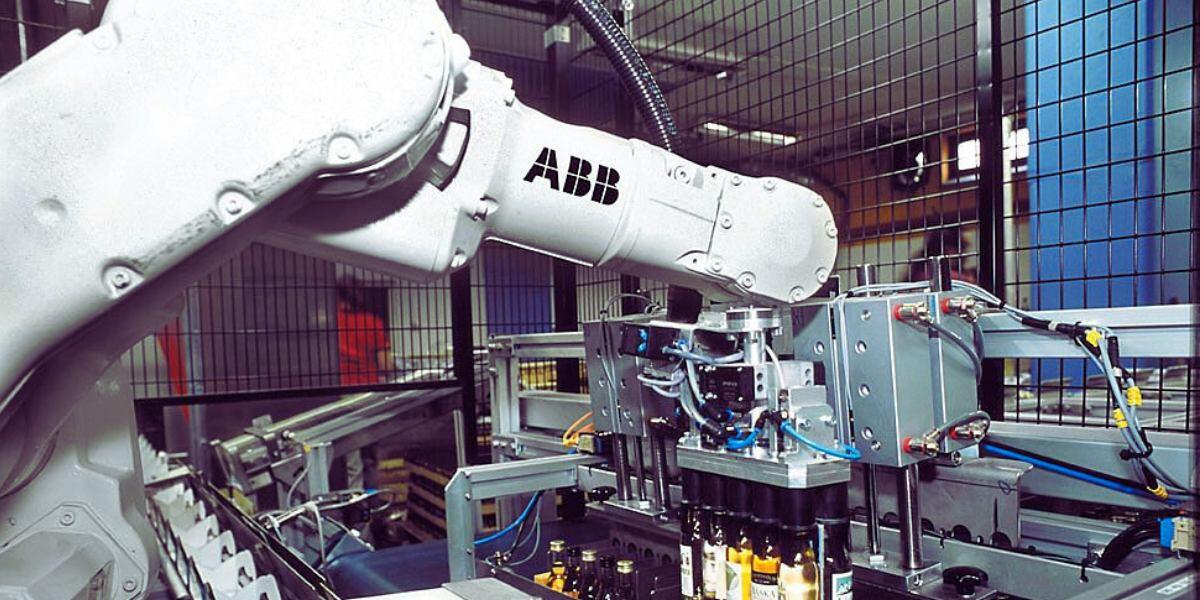

For example, an industrial robot performing palletizing tasks in a factory is a product of robotics. However, a complete automation system that combines this robot with temperature sensors, vision systems, actuators to adjust production, and a control software is an example of mechatronics.

What Is Mechatronics?

Mechatronics is an interdisciplinary field that combines mechanics, electronics, computer science, and control engineering to design and manufacture intelligent systems. Its goal is to create optimized automated solutions by integrating various technologies to solve complex problems. A classic example of mechatronics is an automotive control system that integrates sensors, motors, actuators, and data processing algorithms to optimize vehicle performance.

A typical mechatronic system consists of several key elements:

- Mechanics: The physical structure that allows the device to interact with its environment.

- Electronics: The sensors, actuators, and circuits required to control the system.

- Computer Science: The software and algorithms that enable automation, communication, and decision-making.

- Control Engineering: The systems that regulate and adjust the behavior of the system in real-time.

What Is Robotics?

Robotics, on the other hand, is a branch of engineering focused on the design, construction, and operation of robots, typically to perform physical tasks autonomously or semi-autonomously. Robots can be programmed to execute repetitive, hazardous, or complex tasks in various environments, such as manufacturing, assembly, or surgery.

A typical robot consists of the following components:

- Robotic Arm: Executes physical actions, such as grasping, moving, lifting, or assembling objects.

- Sensors: Used to perceive the robot’s environment and adapt its actions based on received data.

- Controller: A computer system that manages and executes the robot’s programs, determining the sequence of actions.

- End Effectors: Tools attached to the robot (such as grippers, arms, or cameras) to perform specific tasks.

How Do These Two Fields Complement Each Other?

Although mechatronics and robotics are distinct disciplines, they often complement each other in industrial projects. For example, a collaborative robot (cobot) that works alongside a human operator can be the product of a mechatronic approach, combining a robotic arm, sensors, a control system, and software to optimize human interaction. Mechatronics engineers can design and improve these systems by integrating various technologies to maximize the efficiency and precision of robots.