Pick and Place

Gain speed, precision, and reliability

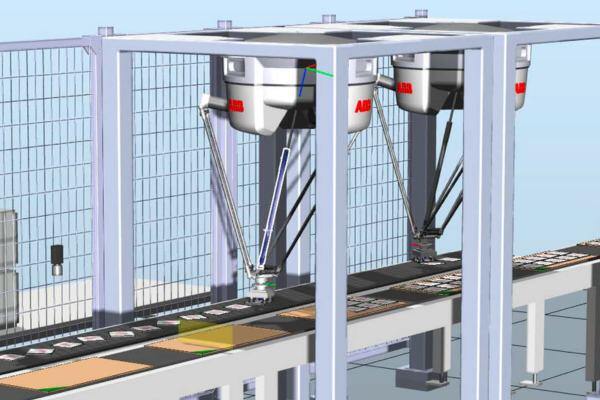

We integrate Pick and Place robotic cells to automate repetitive and critical tasks in your production, packaging, and logistics environments. These robotic solutions precisely move objects from point A to point B while maintaining a high throughput.

Pick and Place Robotic Arms

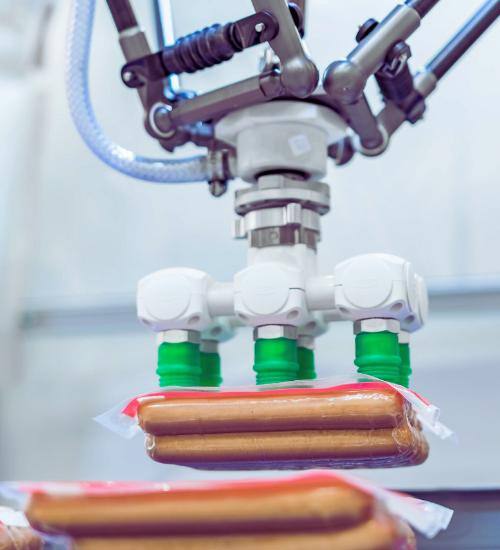

Pick and Place robots are designed to pick up an object from a defined location (on a conveyor, in a bin, on a table) and accurately place it at another location. They are especially effective for quickly handling objects of various sizes, shapes, and materials.

Our systems include:

- Grippers (suction cups, mechanical clamps, soft fingers, etc.) tailored to your products

- Industrial vision cameras to accurately detect, locate, and orient objects

- Custom programming software enabling repeatable and dynamic cycles, with or without visual guidance

Automated Loading of Pouches into Cartons at a High Throughput

Industry: Food Processing

Challenge: A food processing company sought to automate the loading of cashew nut pouches into cartons to meet rising demand, while reducing physical strain on employees. The goal: maintain a high production rate without compromising worker safety.

Deployed Solution: GoFa collaborative robot with suction gripper, working in synergy with operators.

Technical Challenges

- Keep up with a bagging line speed of up to 36 pouches/min

- Prevent injuries (musculoskeletal disorders) caused by repetitive manual handling of 11 kg loads

- Fit the robotic cell into a constrained production area

Solution

The chosen solution was based on integrating a collaborative robot equipped with a suction gripper capable of handling two 1 kg pouches simultaneously. This flexible cell operates safely alongside workers without the need for safety barriers, thanks to its collaborative design and compact footprint.

The cobot was deployed to automatically feed cartons in sync with a recently upgraded bagging line. Initially designed for a throughput of 22 pouches/min, the system was quickly adapted to reach 35–36 pouches/min by adding a second collaborative robot.

Results

- Accelerated ROI through improved labor-to-output ratio

- Upskilling of personnel toward technical roles (robot programming and supervision)

- Reduced workplace injuries from manual material handling

Evaluate your project

We understand that every business is unique, which is why we work closely with you to understand your specific needs and design customized automation solutions. Our team of experts in robotics, vision, and artificial intelligence is here to guide you through every step of your next automation project.

Frequently Asked Questions

It is an industrial robot designed to grab an object from a specific location and place it in another. It can perform this task very quickly, accurately, and repetitively, with or without visual guidance.

Yes. We integrate 2D or 3D vision systems based on your needs. This allows the robot to locate loose objects, adjust its movements based on their orientation, and even verify their conformity before placement.

The timeline depends on the complexity of the application (product type, throughput rate, integration with other equipment).