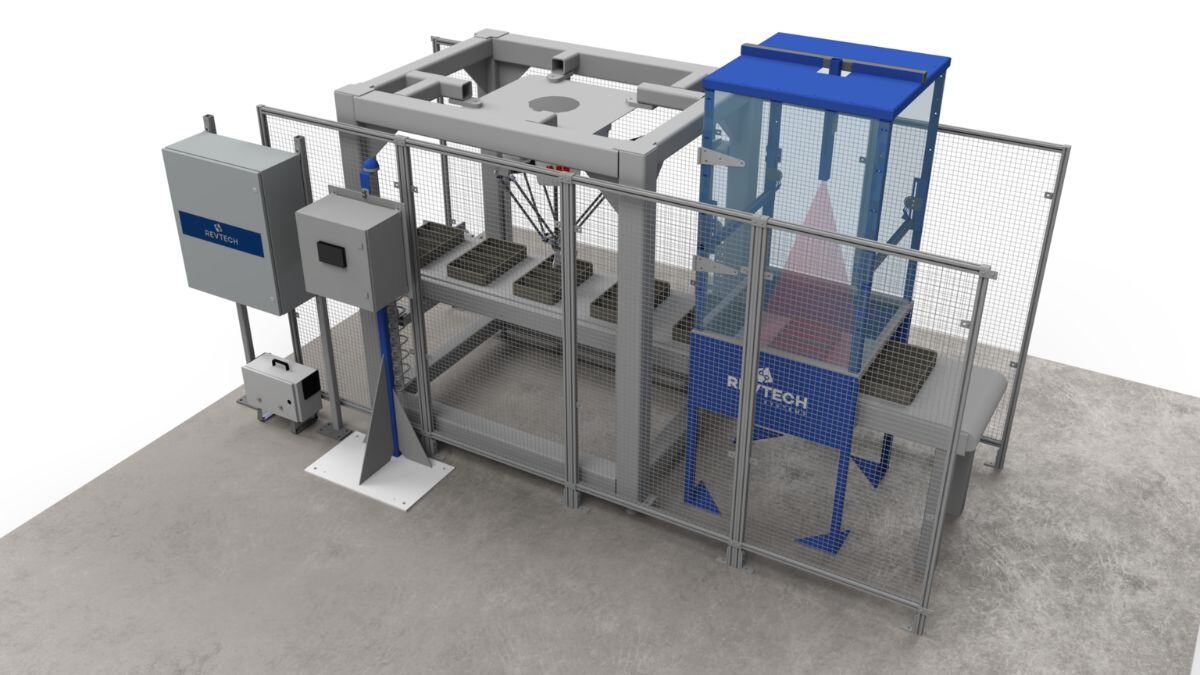

Sorting Robot

The Revtech Difference: Comprehensive Support

Our commitment goes beyond delivering a robotic cell. We understand that implementing and effectively using a sorting robot in your facility can be challenging. That’s why we put support at the heart of our approach. At Revtech, we ensure that your equipment operates at its full potential.

Our experts guide you every step of the way—from assessing your needs to training your teams, programming, and maintaining your systems. This personalized support guarantees successful integration and long-lasting optimization of your processes.

What Are Parallel Robots Used For?

Parallel robots, known for their exceptional speed and large open working area beneath their structure, are primarily used for fast pick-and-place tasks involving moving items on conveyors. They are particularly well-suited for operations where speed takes priority over extreme precision.

AI Vision for Classification and Inspection

AI-based vision is revolutionizing product classification, defect detection, and inspection operations. With advanced pattern recognition and self-learning capabilities, these systems are increasingly effective at handling product variations on production lines.

Evaluate your project

We understand that every business is unique, which is why we work closely with you to understand your specific needs and design customized automation solutions. Our team of experts in robotics, vision, and artificial intelligence is here to guide you through every step of your next automation project.

Frequently Asked Questions

Parallel sorting robots can handle a wide variety of products, whether solid, fragile, lightweight, or bulky. With the addition of customized grippers (such as suction cups, clamps, or magnetic systems) and advanced vision tools, they can efficiently manage food products, industrial parts, and everyday consumer goods.

The integrated vision system enables real-time identification, localization, and inspection of products on the production line. Depending on specific needs, several technologies can be employed:

- 2D Vision for simple contours,

- Color Vision to visually differentiate products,

- 3D Vision for complex or overlapping shapes,

- AI for advanced pattern recognition and self-learning to adapt to product variations.

QUESTION

What Are the Benefits of a Solution Combining a Parallel Robot, Gripper, and Vision System?

This combination offers:

- A reduction in sorting and placement errors,

- Precise real-time product inspection for defect detection,

- Increased flexibility to handle various product types without heavy reconfiguration,

- Higher production speeds while maintaining consistent quality.