Since 2024, the Government of Canada has tightened the rules around the use of Temporary Foreign Workers (TFWs), directly impacting many manufacturing companies in Quebec. For sectors already struggling with recruitment, these measures reduce access to essential labor needed to sustain production. While some companies had already begun shifting toward automation, most are now faced with a pressing reality: without robotics, both growth and survival are at risk.

Understanding the Regulatory Context

The government has lowered the maximum percentage of TFWs allowed in certain industrial sectors. The goal is to encourage local hiring. However, this disproportionately impacts industries where local labor is either insufficient or simply not interested in the available roles.

Direct consequences already observed:

- Shutdowns of entire shifts

- Delayed or refused orders

- Contract penalties

- Higher unit production costs

Access to local workers who are available, trained, and motivated to take on repetitive tasks is shrinking fast. Several factors make the issue worse:

- An aging workforce

- High turnover in low-value positions

- A generational preference for technical or hybrid roles (often office-based)

The result? Even positions historically filled by TFWs are becoming harder to maintain.

Automation as a Systemic Response

Automation frees up local human resources for higher-value roles in supervision, quality, maintenance, and process control, while robots handle:

- Machine loading/unloading

- Palletizing/depalletizing

- Sorting and inspection with machine vision

- Packaging and boxing

Key benefits:

- Reduced dependence on TFWs

- Stable productivity, even during labor shortages

- Lower costs linked to turnover

- Higher product quality through consistent precision

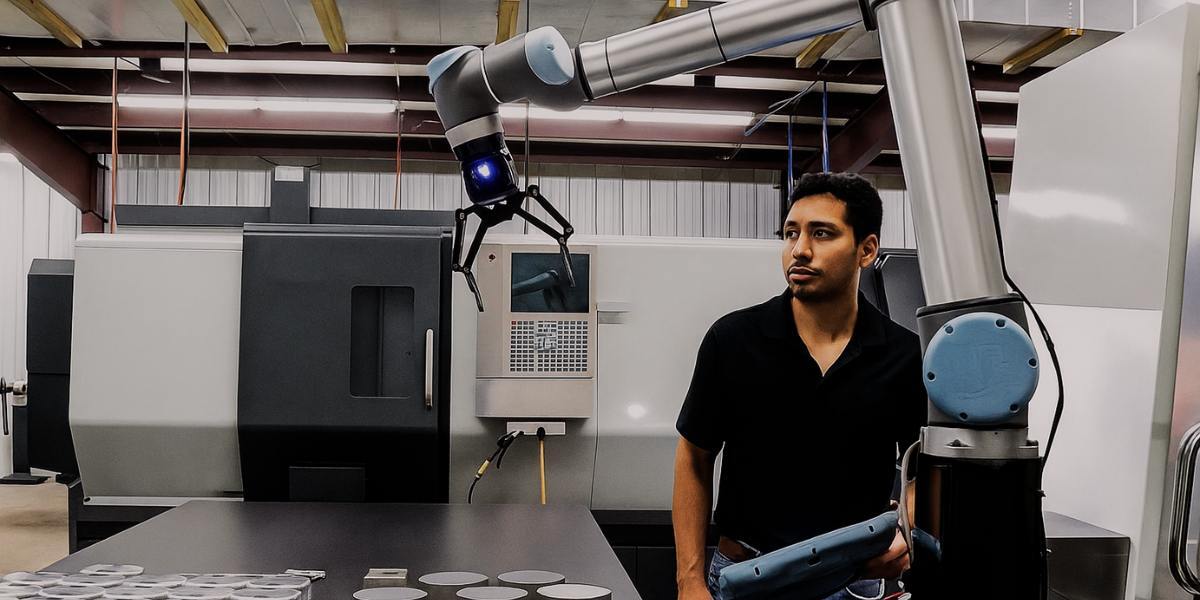

Contrary to popular belief, automation is no longer just for large corporations. Recent advances whether collaborative robots, intelligent 3D vision systems, or specialized solutions like those developed by Pushcorp (leaders in robotic compliance technology) now make it possible to automate applications that were once too complex or simply unfeasible.

These innovations stand out thanks to their technical maturity, proven reliability, and financial accessibility, allowing companies to deploy robotic cells:

- In just a few months

- Without heavy infrastructure

- With a realistic budget

A well-scoped automation project can deliver ROI in under 18 months.

Toward a Hybrid Workforce + Robotics Model

Automation doesn’t mean people disappear from the factory floor. Instead, it creates a more resilient model where operators become cell supervisors, know-how is preserved and elevated, and companies can take on more contracts without fearing a labor shortage. The new restrictions on TFWs are acting as a catalyst: forcing companies to reduce their dependence on external labor and consider durable solutions. For Quebec manufacturers, automation is not just about survival it’s a long-term growth strategy.

FAQ

1. Can robotics fully replace a TFW?

Not in every case. But it can automate the simplest, most repetitive tasks freeing up human resources for critical functions.

2. What are the usual timelines to deploy a robotic cell?

A well-framed project can be designed, built, and operational within 4–8 months.

3. Does automation make my operations more rigid?

Not at all especially if you choose modular and reconfigurable cells. In fact, flexibility is one of the key advantages.

4. What types of equipment are eligible for government subsidies?

Robots, vision systems, automated conveyors, and software tied to automation are all eligible under programs like ESSOR or PSCE.