For years, the strategy was pretty straightforward: make things cheaply overseas, usually in Asia, and keep the high-value work close to home. But that old model is starting to crack. COVID-19, rising geopolitical tensions, and growing pressure to go green have all exposed the risks of relying on long, fragile supply chains.

Now more than ever, a simple but powerful question is taking center stage: why make it elsewhere if we can build it right here?

From Offshoring to Reshoring

We’re in the middle of a major shift in how the world thinks about manufacturing. After decades of sending production to low-wage countries, more and more nations including the U.S., European countries, and slowly but surely, Canada are rethinking that approach.

Terms like reshoring (bringing production back home) and nearshoring (moving it closer to where it’s needed) are popping up more often. And it’s not just about cost anymore. It's about being more resilient, protecting our economic independence, and building the capacity to innovate locally.

A Real Chance for Quebec Manufacturers

For businesses here in Quebec, this shift opens up a huge window of opportunity. Local production can mean more control, faster delivery times, and better quality. It also gives manufacturers the flexibility to adapt quickly and drive innovation from the ground up.

But it’s not as simple as just bringing production back. To make it work, it needs to be smart because let’s face it, we’re dealing with labor shortages, higher local costs, and energy considerations. So, what’s the game-changer? Automation.

Why Robots Make All the Difference

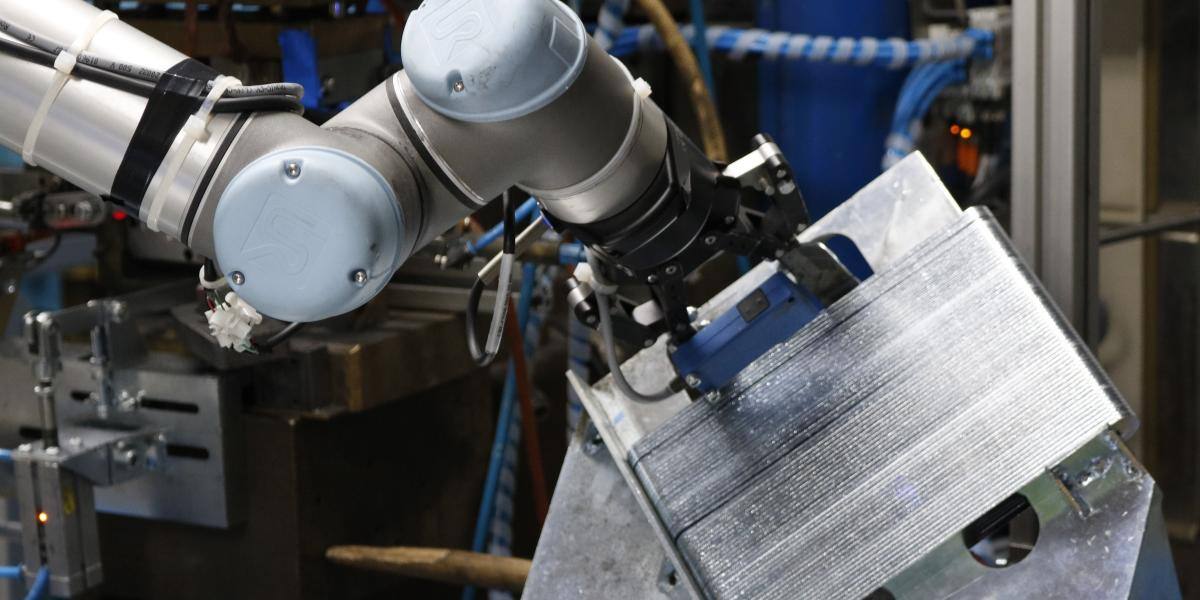

With fewer workers available and an aging workforce, robotics isn’t just nice to have it’s essential. To make reshoring financially viable, you’ve got to think automation from the start.

We’re talking collaborative robots for flexible tasks, robotic cells for repetitive jobs, and AI or vision systems to boost quality. These tools are how we stay competitive while keeping production local.

Better for Business. Better for the Planet.

Reshoring also has a green side. Global supply chains come with a big carbon footprint: cargo ships, overproduction, waste… you name it. Producing locally helps cut that down. Plus, it forces us to own our environmental impact instead of offloading it to other countries. That’s a big step toward building a more ethical, transparent, and sustainable economy.

Quebec Has What It Takes. Now Let’s Make It Happen

We’ve got the space. We’ve got clean electricity. We’ve got the know-how. Quebec has all the right ingredients to become a powerhouse of modern manufacturing.

What’s missing? A stronger push to turn talk into action.

At Revtech, we believe that Quebec’s industrial revival will come through smart, agile automation solutions built for the realities of today. This isn’t some distant dream. It’s already starting. And every manufacturer in the province can be part of it.