Robotics has transformed the manufacturing sector in Quebec over the past two decades. But like any technology, robotic cells age and can become less efficient over time. The question then arises: should you replace the entire line with a brand-new one, or focus on upgrading an existing cell?

At Revtech Systèmes, we believe modernization is a strategic lever for most manufacturers. Upgrading an existing cell not only extends the lifespan of your equipment but also integrates the latest innovations in robotics, artificial vision, and automation — all while keeping costs under control.

Why Upgrading Is Essential in the Lifecycle of a Robotic Cell

A robotic cell is a major investment that should deliver value for many years. However, several factors justify a mid-life upgrade:

- Rapid technological evolution

Robots, sensors, and software evolve at a fast pace. A cell installed 10 years ago may still function but lack the efficiency, precision, or flexibility of today’s standards. - Pressure on productivity

With labor shortages and rising operating costs, every production minute matters. Modernization helps increase throughput and reduce downtime. - Safety and compliance

Industrial safety standards are constantly evolving. Upgrading ensures compliance with the latest regulations while protecting your workforce. - Extending asset lifespan

Instead of replacing an entire line at high cost, a targeted upgrade extends the useful life of robots and equipment. - Adding new functions

Integrating vision systems, collaborative robots, or mobile robots can transform an existing cell to meet new production realities.

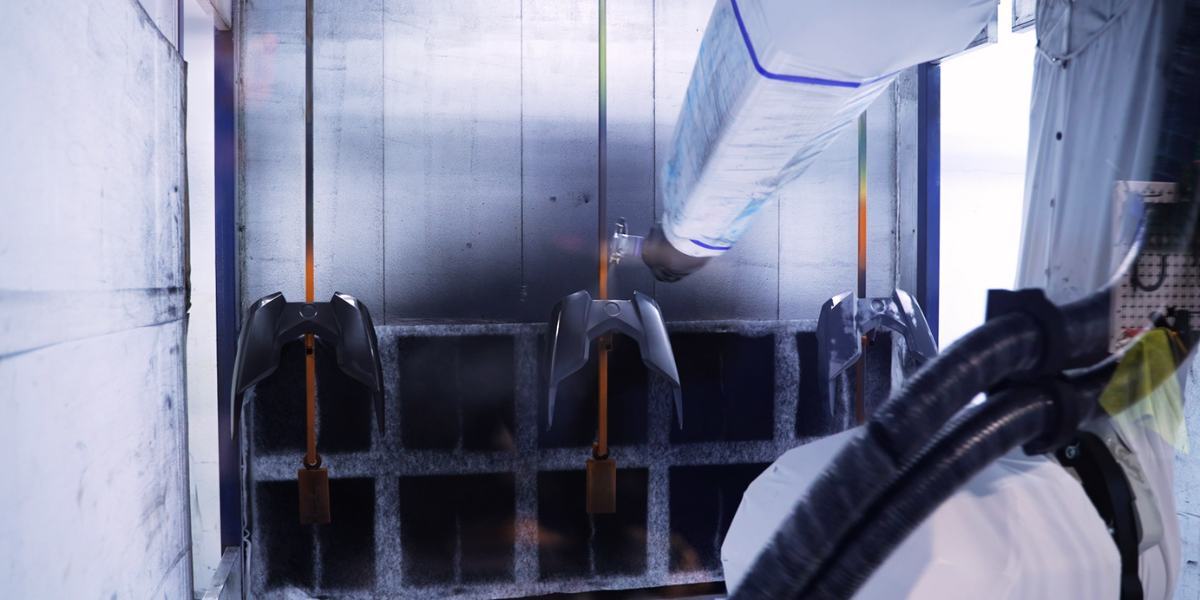

Case Study: Modernization at Chabot Carrosserie

A strong example of the value of modernization is the project recently carried out at Chabot Carrosserie.

Revtech Systems replaced a complete automated painting line, including 6 ABB industrial robots. At the same time, several peripheral devices were upgraded to ensure optimal integration.

Results achieved:

- Improved quality and consistency of the paint finish.

- Reduced maintenance costs thanks to more reliable equipment.

- Greater flexibility to integrate future technological updates.

- Accelerated ROI compared to replacing the entire line.

This project demonstrates how modernization can transform an aging cell into a high-performance, durable production asset.

Pre-Engineering: The Decisive Step

The foundation of a successful modernization lies in pre-engineering. Too often, manufacturers want a quick overall price without going through this step. Yet it is essential to avoid costly surprises.

What pre-engineering includes:

- Full documentation of the current cell (equipment, sequence, signals, HMI, sensors, etc.).

- Analysis of strengths and weaknesses of the line.

- Identification of the best modernization strategies based on your objectives.

- Preparation of a precise and detailed final proposal, including all equipment, options, and integration costs.

Why it is indispensable:

- Reduces the risk of budget overruns.

- Secures the project by ensuring compatibility of new equipment.

- Provides a fair comparison of modernization vs. replacement.

In short: pre-engineering is an investment that safeguards the profitability of the entire project.

The Real Cost of an Upgrade

Upgrading an existing robotic cell isn’t just a cost-saving option: it’s a strategic decision that extends asset life, improves processes, and helps manufacturers remain competitive in today’s demanding market. By focusing on upgrading existing cells, manufacturing decision-makers gain on several fronts:

- Increased profitability: extending asset life while improving performance.

- Agility: adapting quickly to new market demands.

- Safety: stronger compliance and reduced accident risk.

- Competitiveness: staying ahead despite labor shortages.

- Sustainability: avoiding waste linked to replacing equipment that is still usable.

FAQs

Is it always better to modernize than to replace?

Not always. If the cell structure is sound, modernization is usually more cost-effective. But if equipment is too outdated, full replacement may be the better option. Pre-engineering determines the right strategy.

Will my teams need complete retraining?

No. A targeted training program is generally sufficient to get operators and technicians comfortable with new tools..

Which industries benefit most from upgrading?

Virtually all manufacturing sectors — from food processing to metal, wood, and plastics. Anywhere robotic cells exist, modernization is a performance lever.

Why choose Revtech Systems?

Revtech is the first robotics integrator in Canada to be certified ABB Service Value Provider. We bring unique expertise in industrial, collaborative, and mobile robotics, as well as in artificial vision systems.